How Fine Metallurgy Crafts Reliable Locks: Inside Our Manufacturing Process

The secret behind a truly reliable lock lies not just in its design, but in how it’s made. At Fine Metallurgy, every lock is the result of years of research, rigorous material selection, and a well-trained production team. Our manufacturing facility in Aligarh uses state-of-the-art machines to cut, assemble, and test every component with precision.

From raw brass and zinc to finished locking systems, each product goes through strict quality checks. We test for smooth key operation, resistance to breakage, weatherproofing, and overall durability. This commitment to excellence is why our locks are trusted by institutions and dealers across India.

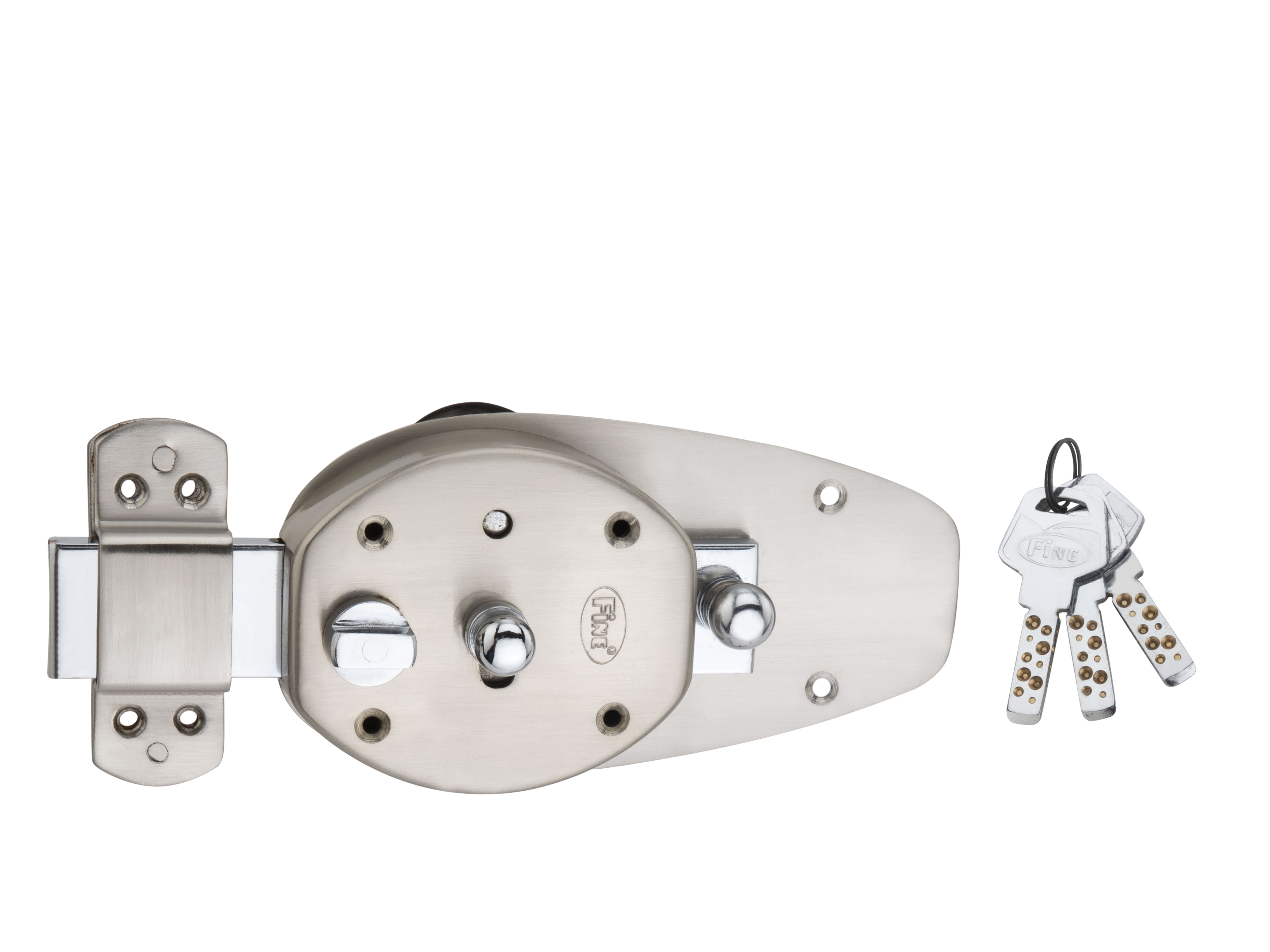

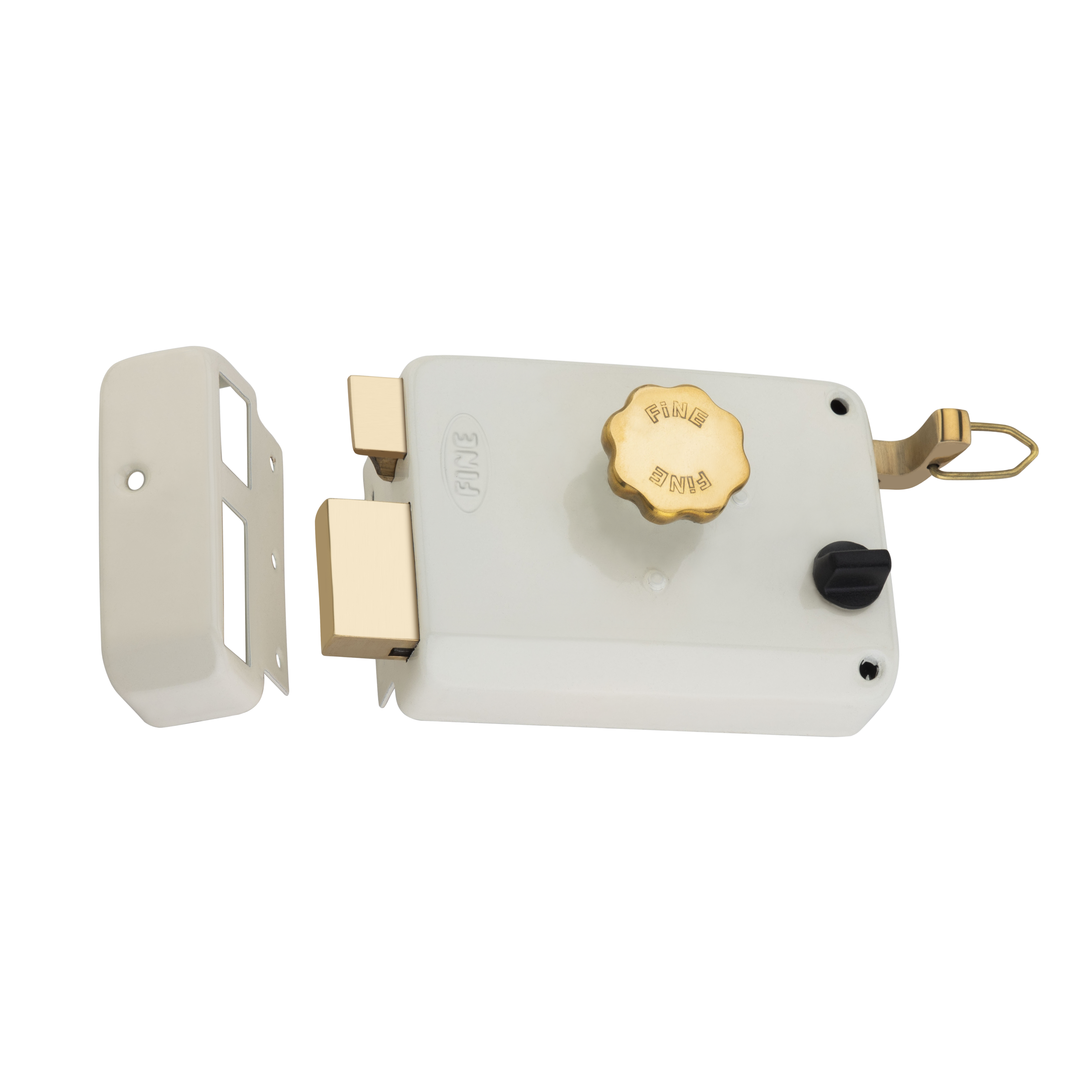

What sets Fine Metallurgy apart is our end-to-end control over the manufacturing process. We don’t just assemble parts — we manufacture critical components in-house. Our forging and casting processes ensure structural strength, while CNC machining provides consistency in every piece. Surface treatments such as nickel and chrome plating not only give our locks a premium finish but also enhance corrosion resistance for extended outdoor use.

Our in-house R&D department constantly works to improve locking technologies, incorporating customer feedback and emerging market needs. Whether it’s biometric integration, anti-pick mechanisms, or eco-friendly coating techniques, we strive to innovate without compromising reliability.

The human touch also plays a major role. Skilled technicians inspect each lock manually before packaging to ensure that only flawless products leave our facility. This blend of technology, craftsmanship, and dedication is what makes a Fine Metallurgy lock truly dependable — built to secure homes, offices, and commercial spaces for years to come.